The back bay. This is the carder (left), drafter (right) and the spinner and plyer in the back. The vacuum hose runs from the carder to a box that collects any loose fiber for the felting table.

The front bay. This is the fiber separator (left), the steamer (front right), the felting table (back right) as well as the cone and skein winders (not seen)

The washing system, worktable and sink

Picker and drying racks

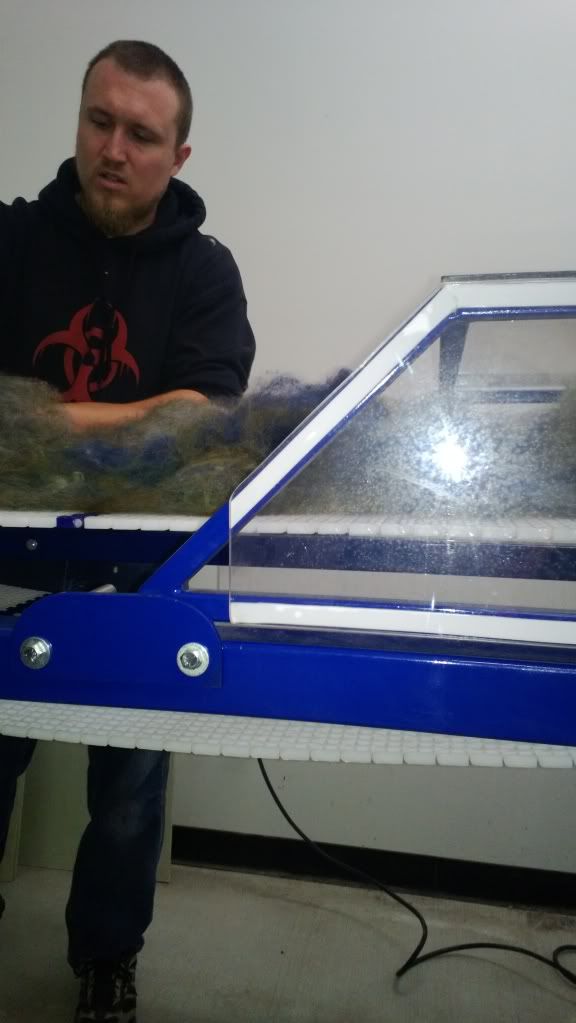

This is what fiber looks like out of the picker room. It's opened up and very fluffy and loose. This is some Shetland that was dyed about two weeks ago.

Then it gets fed into the carder.

Then through the drafter

And then it gets spun, plied and steamed before being wound into skeins. Our very first skein is tiny, about 54 yards, and is currently hanging up to dry after having the processing oils rinsed out.

So all in all, not a bad first day. We have a few things to tweak, but it was awesome to get in and start working on the machines.